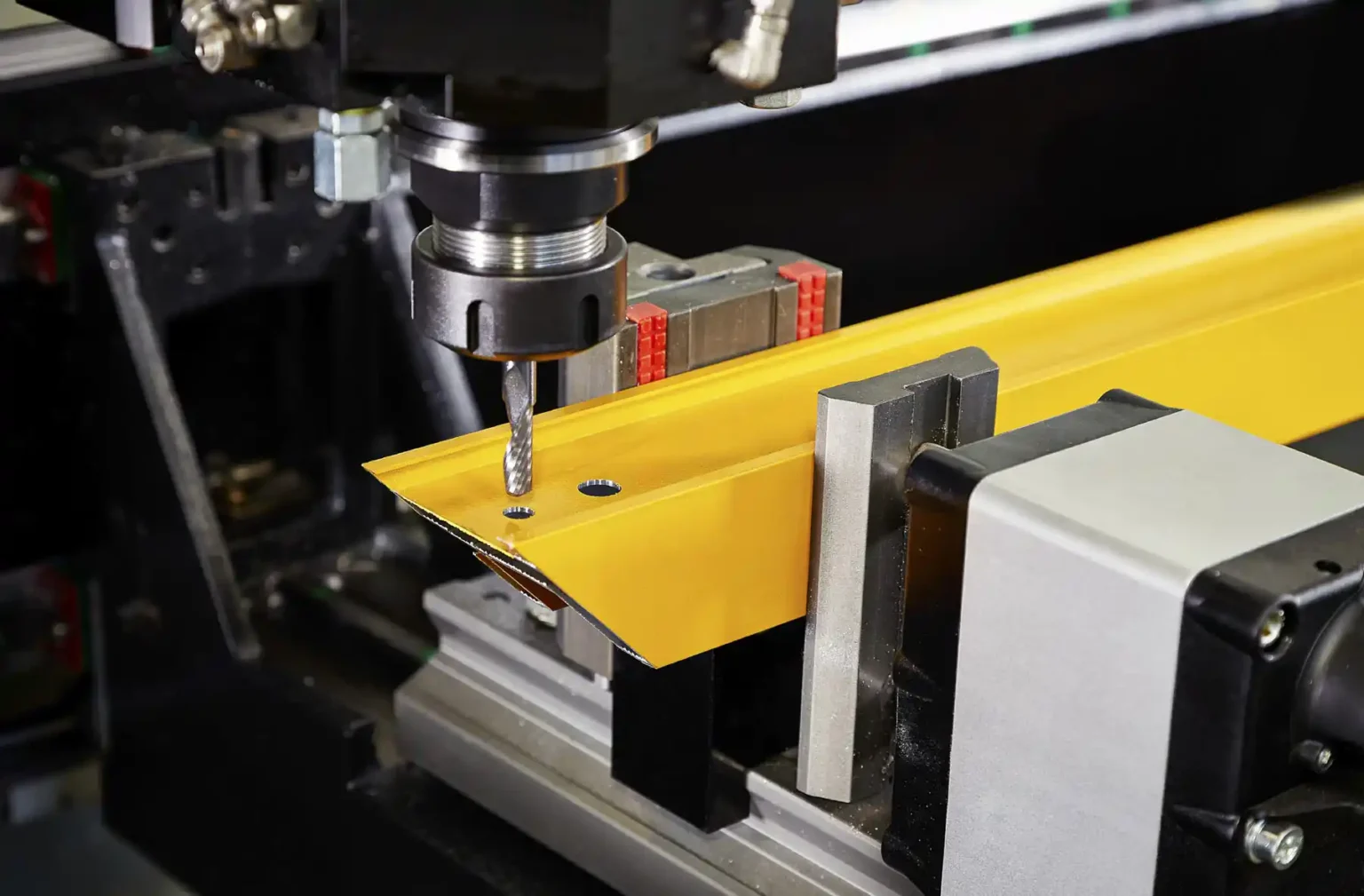

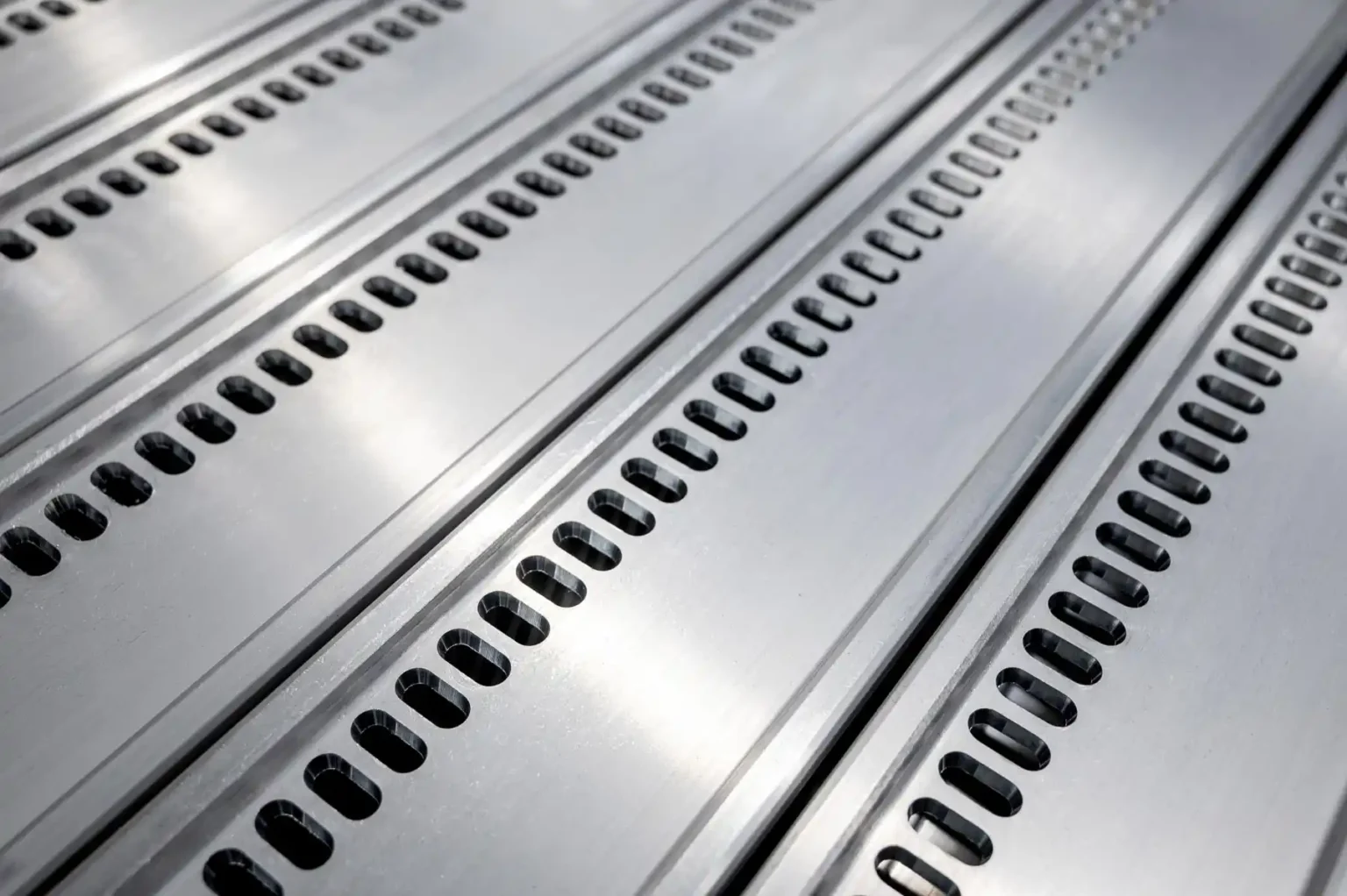

Are you looking for high-quality aluminium profiles at a competitive price? ALUDEX is the specialist in the production and processing of aluminium profiles. This applies to both custom-made aluminium profiles and standard profiles. ALUDEX takes care of the entire production process and stands for high-quality service and personal attention.

With us, you benefit from many advantages, such as:

- Everything under one roof

- Large production capacity

- 100% European production

- Sustainable production process

- Production in accordance with European quality guidelines

- Economies of scale

- Delivery throughout Europe